Bacchetta G20 with Grin All Axle hub motor, Phaserunner controller, CycleAnalyst v3, and BionX 13S/48V battery. Summer tire configuration, Schwalbe Marathon Plus on 26" back wheel, and Snafu BMX 2.10 on 20" (406) front wheel. If the front wheel isn't perfectly true, the 2.10" wide tire rubs on the sides of the fork. A 2.0" wide tire solves that problem and is still wide enough to provide sufficient traction.

Photo of eG20 at Mojo Coffee ("Pandemic Mojo"), 22 Mar 2020. Running with 14S/52V Hailong S39-03 "Shark" battery. Still have Schwalbe studded winter tires on. The 14S battery actually allows you to get past 35MPH.

Posing shamelessly with the usual Saturday morning riff-raff-riders on the end of Minnesota's very own Bridge to Nowhere. Years ago, it was a swing bridge with with a toll-booth: for 25 cents you could get to the other side of the Mississippi. I'm back to using the BionX battery. Note the Luna Mighty Mini (14S2P, Samsung Q30 cells) "spare" battery pack sitting on top of the main tube in front of the seat. Both of these batteries suffered from bad cases of "BMS"(Battery Murdering System) syndrome, and are now happily living out their post-retirement years without a BMS. You just can't keep good lipo cells down, as long as you meet their basic needs. (That's Paul, not me, posing in the front of the bike. I'm the one taking the photo.)

Return to Top of Page Return to Main Menu

See the continuation of thesetrip stats for the HP Velotechnik StreetMachine.

Reference to this page on the web: http://erowbike.com/eG20#trip_stats

Minimum amps, expressed as a negative value, represents the peak current resulting from regenerative braking. This is limited to approximately 15 amps to protect whichever battery is being used from being overcharged. I usually program the CA to limit forward current to 30 amps to avoid over-stressing the battery as well, since this gives me all the power I typically need. The motor and controller will go to 90 amps of input current without problems. The maxium speed of 35MPH is only if using the 14S (52V) battery. The transition of pedaling to a higher speed after reaching WOT is very smooth.

| Dist miles |

Time hr:min |

Speed Max/Avg |

Amps Min/Max |

Regen % |

Temp C Max/Avg |

WattHrs Used Total/Mile |

WattHrs Recharge |

Pack Voltage |

Notes & Misc. |

|---|---|---|---|---|---|---|---|---|---|

| 9.8 | 0:51 | 35.1/11.5 | -14/29 | 6.7 | 38/24 | 137.9/13.2 | 150 | 14S | 23 Feb 2020, high 40's; First ride on eG20. |

| 11.9 | 1:02 | 23.5/11.4 | -9.8/29.4 | 4.3 | 6/3 | 102.9/8.2 | 120 | 14S | First Saturday OUST ride, 14 Mar 2020; 22 degree temps, CHILLY! |

| 22.3 | 1:46 | 36.8/12.5 | -10.6/29.4 | 7.3 | 22/16 | 230.2/9.6 | 270 | 14S | 22 Mar 2010; 25/G35 MPH winds; 32-44 F temps; 21.5 mi. per GPS; |

| 35 | 2:42 | 35/12.9 | -15.5/29.5 | 4.6 | 30/25 | 317.5/8.6 | 350 | 14S | 30 Mar 2020; avg 19MPH first 4 miles to rendezvous, 17 wHrs/mi, almost all throttle; |

| 18 | 1:31 | 35.6/11.7 | -15.4/28.7 | 16.4 | 24.7/22 | 148.7/7.1 | 150 | 14S | 31 Mar 2020; "hilly" trip (953' elev gain); going UP High Bridge in 3:45/10.3 mi/h |

| 38 | 2:56 | 31.8/12.9 | na/21 | na | na | 331.6/8.7 | 390 | 14S | 5 Apr 2020; trip on DAS upright with MAC 3* motor; 1,233' elev gain to Shoreview; HWhrs:223 AvgHW:123 Avg RPM:44; battery icon = 1/3 left |

| 19 | 1:41 | 26.8/10.2 | -13.2/28 | 17.2 | 24/21 | 127.7/6.4 | 180 | 13S | 18 Apr 2020; first ride after cable repair; Speed (white) wire no longer sending data, probably due to a broken/shorted Hall signal wire; hilly ride, seeing a max regen of 19.2% after descent of the High Bridge; no longer a smooth start when motor is heavily loaded and at dead stop; recharged battery with solar only. |

| 19.3 | 1:40 | 29.3/11.5 | -11.2/28.8 | 22.2 | 28.2/26.8 | 102.4/5.3 | ~110 | 13S | 25 Apr 2020: great test of motor torque - went through 70' of deep soft sand (road construction on Summit/Ayd Mill bridge); WOT kept bike moving, drawing ~ 1,400 watts (29 amps at 48 volts) from BionX 13S battery; used 5.3 wattHours/mi but still felt like I got more than enough assistance; battery icon appeared still 3/4 full at end of ride. |

| 19.9 | 1:36 | 31.4/12.2 | -15.7/28.3 | 11.9 | 35.3/28.6 | 150.5/7.6 | 13S | 30 Apr 2020; test max regen while slowing steep downhill to Lilydale Marina -- nearly -16 amps into BionX 13S battery; | |

| 21.9 | 1:17 | 32/17.1 | -15.4/29 | 10.1 | 42/30 | 312.3/14.3 | 324.5 | 13S | Emphasis on speed, especially during first half of ride; LOTS of throttle use resulting in 14+ watt-hours/mile, but a 17MPH average. BionX battery was down to 46.7 volts; gauge showing 5 pixels remaining. |

| 5.8 | 0:20 | 28.8/17.4 | -15.4/28.3 | 7.5 | 46.6/35.7 | 123.8/21.4 | 13S | Short trip; haul 80 pound load in trailer up Randolph hill over 35E; avg speed 17.42MPH for whole trip! No shortage of torque or braking, steering is fine. | |

| 63.63 | 5:18 | 27.6/12 | -11.7/28 | 17.8 | 33.6/37.1 | 376.6/5.9 | 250 | 13S & 14S | Long trip, to WI, both bridges across St Croix River; BionX 13S suddenly died at 51.7 miles/289.5Whrs/5.05Ahrs?/4:17hrs; used Luna Mighty Mini (14S/2P-30Q cells) as spare. Quite a bit of hill climbing, plus long, steep downhills with lots of regen(17.8%/1.15 amp hours vs. 7.6 forward amp hours!). A big chunk of this regen came from a slowish descent down Myrtle St into downtown Stillwater. |

| 32 | 2:32 | 32/12.6 | -15.2/28.6 | 15 | 40.5/33.9 | 250.4/7.8 | 213.4 | 13S | Sat, 2 Jun 2020; Roundtrip to Hopkins Depot; mostly flat terrain. |

| 39.6 | 2:54 | 34.8/13.6 | -14.1/28.6 | 13.2 | 51/41 | 308.9/7.8 | 13S | ? | |

| 46.9 | 3:25 | 37.4/13.7 | -14.1/29.6 | 11.5 | 43/34 | 352.9/6.7 | 13S | 15 Aug 2020; flat terrain; first 14 miles were close to 20MPH average; first significant miles on 2nd Grin All-Axle motor -- works great! Pack voltage down to 46V at end of ride, | |

| 52.8 | 4:32 | 21/11.7 | -9.64/29.4 | 4.8 | 40.2/33.5 | 305.29/5.5 | 13S | 15 Aug 2020; flat terrain (RT to Excelsior MN); Pack voltage down to 46.9V at end of ride, | |

| 31 | 2:44 | 26/11.3 | -14.2/29.7 | 9 | 27/22 | 286.4/8.4 | 295 | 14S | 31 Oct 2020 (Halloween); Luna Mighty Mini Pack voltage down to 41.5V (3V per cell) at end of ride, with pack struggling to pump out 100 watts. (I thought I was using BionX main pack instead of Luna backup pack!) Min. V dropped to 38.5 when pack was depleted and throttle floored. These Samsung Q30 cells @ 2P were able to climb the steepest hills pushing 1,500 watts into the Grin all-axle hubbie. The CA just rolled back the watts, but never actually 'shut down' the assist level. I'd rate this pack @ 280 WHrs, or at least a solid 0.25kWHr, using 28 18650 cells. Recharged pack to 58.5, using 295.4 of free solar watt hours. |

| 36 | 2:39 (3:31 elapsed) | 30/13.7 | -14.2/29.7 | 6.8 | 45/38 | 372/13516.6/14.4 | 382(7.8AHrs) | 13S & 14S | 3 Apr 2021: Rode BionX battery (13S) until it hit LVC/40V (44.6V pack voltage at rest after a few minutes and no pixels in battery icon on CA3). Full capacity was used up per CA3 after 1 hour 41 minutes (Sigma said moving time at this point was 3:31). Energy used was 7.7 AHrs (@48.3V)/372 WHrs. Regen for the BionX battery portion of ride was 5.8%. So, *actual* capacity of BionX pack early in 2021 is 372 watt hours. If it was 10.5AHrs x 48V = 504WHrs originally, it has 74% of nominal capacity left after xx years. The internal resistance of this battery, measured by CA3 at rest after depletion was 0.178 ohms (the Mighty Mini was 0.156 ohms). So, with liberal use of the throttle, this BionX battery is still good for 25+ miles per charge. Batteries are "long life" charged to 4.15V per cell, so the *absolute* capacity of battery would be a bit higher. The recharge process took the BionX from 45.5V (next-day 'recovery' voltage, up 0.9V) to 54.2V HOC ("hot off the charger"). |

| Dist miles |

Time hr:min |

Speed Max/Avg |

Amps Min/Max |

Regen % |

Temp C Max/Avg |

WattHrs Used Total/Mile |

WattHrs Recharge |

Pack Voltage |

Notes & Misc. |

First test ride results, 23 Feb 2020, Sunday; UNUSUALLY high temps in the upper 40's, very sunny. This trip consisted of going up Highland Pkwy to Snelling -- one mile uphill, mostly on throttle. Return from Snelling is almost all downhill, did mostly pedaling with purposeful regen on steeper inclines. Next was going up and down Finn once or twice, again mostly on throttle. Then to Fort Snelling overlook and back (approx 6 miles of the 9.8 mile trip) - this was also mostly on throttle. Max speed was reached using WOT going downhill on Ford Pkwy to the bridge, using a nearly constant 800+ watts. I crashed the bike on a 'trail curb derail' maneuver to test the battery rail -- it passed with flying (literally) colors -- my left knee didn't like it very much. I finished the ride home with 100% throttle. It was easy to spin the front wheel (studded tire) in snow/ice or on sandy pavement if opening the throttle quickly (don't do that so much). Leaning forward helps a lot if you need to accelerate quickly. I didn't do the full torque test going up/down the North entrance of Hidden Falls Park this time.

Trip Miles: 9.768 [BC5.12 indicates 10.39 mi; WS= 1600+mm?] [GPS indicated 9.42, "First eCherry G20 Ride"; although GPS reading seemed low after Snelling and back portion, which is a measured 2 miles via map geography] CA with wheelsize ("WS") setting of 1,565 mm says 9.8, GPS says 9.4. With the Schwalbe Winter 20", the WS should be closer to 1,545 mm.

Max Temp: 38; Avg Tmp: 24;

Max Sp: 35.1MPH; Avg Sp: 11.5 MPH;

Trip Time: 50 mins 54 secs;

AMin: -14.2 (via ebrake);

AMax: 28.96; VMin: 49.9; (approx 5V sag at max load for this trip)

%Regen: 6.7%; Regen Ah: 0.1605;

Watt-hrs: 137.94; Wh/mi: 13.2;

Indicated battery voltage at end of trip: 54.9;

Amp hours (Ah) used: 2.38;

Watt-hrs put back into battery pack per watt-meter: 150 (138 out, 150 in; == 92% efficiency)

First Saturday OUST ride, 14 Mar 2020; 22 degree temps CHILLY. Down river, Shepherd, Otto, uphill to Snelling. Pulled a short but steep hill at nearly 1,400 watts, on dry pavement; no evidence of slippage, even with leaning fully back and having studded tires. Turns out the right handlebar was seriously bent inward due to the previous crash. Forgot to log trip with GPS (Strava).

Photo of eg20_ca_13-2whrs-mile

Photos of eg20 being used as a 'tractor trailer'. Still can do 30MPH and maintain speeds uphill. Regen braking feels very safe when pulling a trailer. The old BionX 13S/48V battery can absorb about 750 watts of braking force, which is sufficient for normal use, and has provided up to 22% regen. The homemade air coupler trailer hitch which replaces the factory Burley hitch is much easier to use and has been reliable so far.

eg20 picking up 50 pounds of Canadian oatmeal from the Hampden Park Coop (May 2020)

eg20 picking up 80 pounds of potting soil from Leitner's, a local nursery

eg20 picking up ANOTHER 50 pounds of Canadian oatmeal from the Hampden Park Coop (November 2020) Note that for winter use I switched back to using the 14S UPP Hailong battery pack, from the 13S BionX battery.

Photo of the eG20 20" front wheel, fitted with a Schwalbe Marathon Winter tire. It has 4 rows of carbide studs for winter use here in Minnesota. The "true" 20 inch (DIN 406) wheels can have tire circumferences anywhere from 1500 to 1600 or more millimeters, depending on the tire's profile. The default circumference for 20"/406mm tires is typically 1500mm.

See the Speed - Distance - RPM section of this site for more information about how this works with a Grin CA computer.

20" Tire models Circumference (mm)

==========================================================================

Snafu 1.95" BMX @ 60lbs 1559 [130 psi Max], with RhinoDillo inserts

Snafu 2.10" BMX @ 60lbs 1559 @1560:19.29vs19.26GPS;99.8% acc. [1559:19.91vs19.89GPS:99.899%; 1558:17.18vs17.16GPS:99.88%]

Schwalbe Big Apple Plus 1658 via tape measure, on eRowBike

Schwalbe Marathon Racer 1563 on G20 front wheel

Schwalbe Marathon Winter 1545 studded 20" tires, with RhinoDillo inserts

Odysee Aitkin 2.35" BMX 1658 too wide for G20 front fork!

Note that the Snafu 2.10" is the absolute max width tire for G20 (and probably G26) front fork! Unless the wheel's lateral run-out is near zero, the rubber will rub on the fork sides. A nominal 2.00" would be a more practical limit, and the 1.95" (see below) is a perfect fit.

Photo of the CA screen with the circumference of 1,565mm set for the 20" winter front wheel.

See the Speed - Distance - RPM section of this site for more information about how this works with a Grin CA computer.

This is the 'new' (second) Grin All-Axle motor installed on eG20 on 10 Aug 2020. Debbie had mercy on me after I stupidly allowed an axle spinout and just had Grin ship a new motor so I could repent at leisure, fixing my original All-Axle motor when it was convenient for me. Note the Snafu tire here is only 1.95" wide, and fits the eG20 fork with plenty of clearance on both sides. The Planet Bike front fender will also fit this smaller tire, although two of its aluminum rivets corroded away over time. Fortunately everything else is either plastic or stainless steel, so the fender will reappear here after being repaired (which is now done -- with bigger 3/16" aluminum rivets this time). The Clarks 160mm disc brake rotor was picked up (used) from our neighborhood "Seven Spokes" women-owned/run LBS.

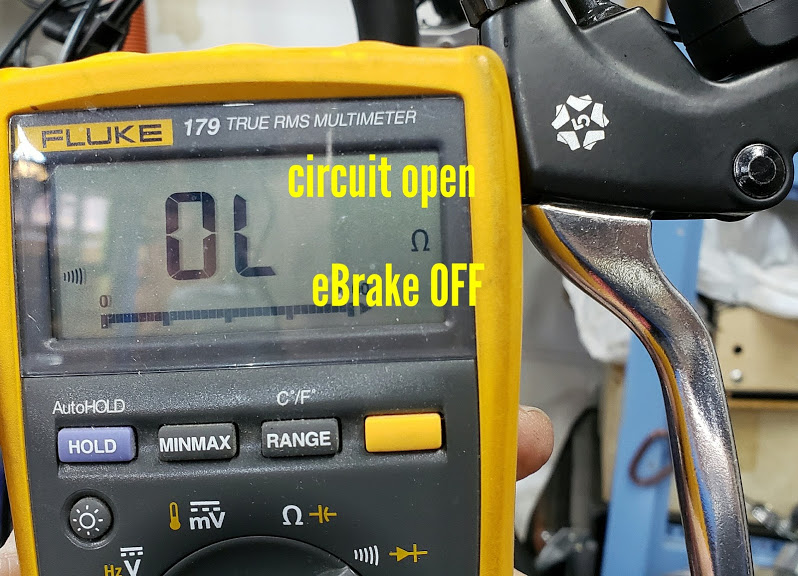

Photo of the eG20's ebrake in the OFF position, which prevents the ebrake signal line from being shorted to ground.

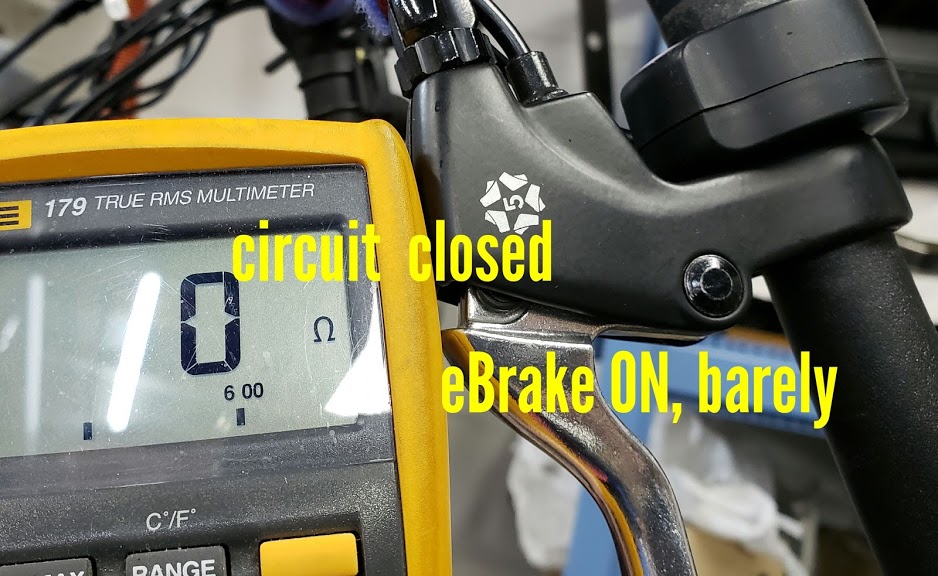

Below is a photo of the eG20's ebrake in the ON position, which shorts the ebrake signal line to ground. Notice how little lever movement is required. At this point, the mechanical disc brake calipers haven't even begun to move yet.

Since I use a variety of traction battery packs on a variety of bikes for prototyping, testing and development, I need a method which allows the safe mounting of different batteries on a given bike. Here I'm experimenting with using a thick-walled 22mm aluminum tube to which I can attach a variety of battery mounting plates. The 22mm format is handy because it's commonly used for bike handlebars, so a variety of clamps are available for it.

Example of a Bacchetta recumbent (not mine) with "minimalist" custom BionX battery mount.

The frame clamps shown below were made from 5/8" polyethelyne scraps from a surplus store (thanks Axeman!). The Bacchetta proprietary oval tube shape was copied from a genuine (and pricey!) TerraTrike Bacchetta frame clamp machined out of aluminum by them (see photo below this one). A bitmap of a pencil tracing was imported into VCarve and then converted into vectors, followed by a a bit of node editing, and then machined using JPods Handibot CNC machine. I modified the clamps a bit so that both sides would be a bit beefier, owing to the use of plastic vs aluminum. The "rail" is a piece of 22mm OD beefy aluminum tube ("handlebar stock") left over from a rowbike project. The M22 rail clamps are made from some dumpster dive (thanks "The Finn") aluminum straps. All nuts and bolts are stainless steel.

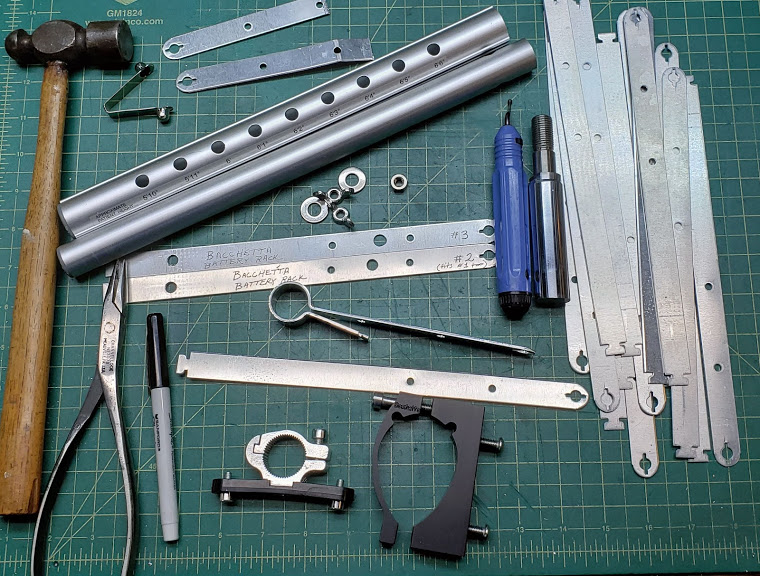

Shown below are the various parts used to make the DIY rail clamps. The aluminum straps are initially bent on the hydraulic press and then finished using a vise. The finishing form is a cutoff from a Lexus SC300 scrapped shock absorber strut, shown just right of the blue-handled deburring tool. The shock strut just happens to be the perfect diameter for finishing the shape of the clamp so it slides on the tube until the bolt is tightened. Plus, it's a nice "shiny object," which everyone knows I have a weakness for.

The following view is the left side of the front fork and wheel with the quick release skewer removed. This is the side that the motor's wires enter and exit, while the torque arm is on the opposite side.

Below are the photos of the L10 wire bundle sheared against the front fork when the torque arm retaining/locking bolt got bumped out and the motor "spun out" near end of 31 Mar 2020 ride. This fault was entirely mine -- not the vendor's -- due to my forgetting to tighten the locknut attaching the torque arm to the front fork frame. An opportunity to learn well seized upon.

The three big phase wires (blue, yellow, green) are clearly visible. Seven additional conductors carry the Hall signals (five wires), temperature/thermistor sensor (1 wire/grey), and speed (1 wire/white). The three Hall sensor data lines (blue, yellow, green) are bundled inside a foil sheath to reduce EMI. The red and black 5V supply lines are part of the main bundle of wires.

For repairing the above damage to the motor's input wiring, see this youtube video by GRIN Tech. After carefully separating all of the individual wires, I tested the phase and Hall sensor wires using the ebike tester and discovered that all of the PHASE wires were still intact -- conductively speaking. The big phase wires were bruised, but most of the damage was limited to the insulation, and very few strands were actually severed. The Hall tests were another story, whereby there appeared to be conductivity on all three Halls, but the pattern on one of the Halls didn't look quite right. Since this motor/controller combination *can* run in sensorless mode, I thought I'd keep my fingers crossed and go for it. I cleaned the bundle with alcohol and a toothbrush and then applied the first coat of the liquid electrical tape. I also tested the motor with a Grinfineon controller on the BogieDyno, and it ran well, although I did NOT run it loaded, nor from a stalled dead stop condition. The Grinfineon controller also supports sensorless operation, so the jury is still out on the Hall sensors. I'll add a second/third coat of liquid tape and finish up with marine-grade heat shrink tubing, and see how this works in real life. [Edit: It worked fine, except one of the Hall sensor wires must still be broken, so I have to 'kick-start' the motor to get rolling and don't have a speed/distance measurement function anymore.] The only 'real' repair for this situation is to take the motor apart and replace the wire bundle, which I plan on doing. An alternative solution is to have your spouse buy you another motor so you can ride while procrastinating. This second approach is working extremely well so far.

While not related to e-assist, other issues can beset a bike. Here we see damage that was done while the bike was in possession of a thief who clearly didn't understand recumbent bikes. This damage wasn't discovered until Nov 2020, nine years after the bike was in the thief's possession for nearly three weeks. Several other visible intances of damage were immediately fixed upon recovering this stolen bike, but the damaged spokes weren't discovered until the original cassette was removed for replacement. The plausible theory is that the thief allowed the drive chain to slip off the innermost gear and rub against the spokes while attempting to ride the bike with extreme force on the pedals. Since the rear derailleur's limit screw was in perfect adjustment at the time of the theft, the chain was likely derailed via some other means. This bike has been ridden for thousands of miles since the theft incident, so one can presume that these stainless steel spokes have a decent safety margin. Since this wheel has been run at speeds over 30MPH, and has carried some significant pack loads, as well as pulling a loaded bike trailer, we can conclude that a decent quality wheel can sustain some damage and still do its job. I was thinking of just getting a new wheel, but new reasonably priced 26" wheels are impossible to find during the Covid pandemic. So, 8 new 256mm spokes are on order from Harris Cyclery (Sheldon Brown's outfit). This wheel will then be shod with a new 2" wide Schwalbe Winter Marathon Plus studded (4 rows) tire for the winter.

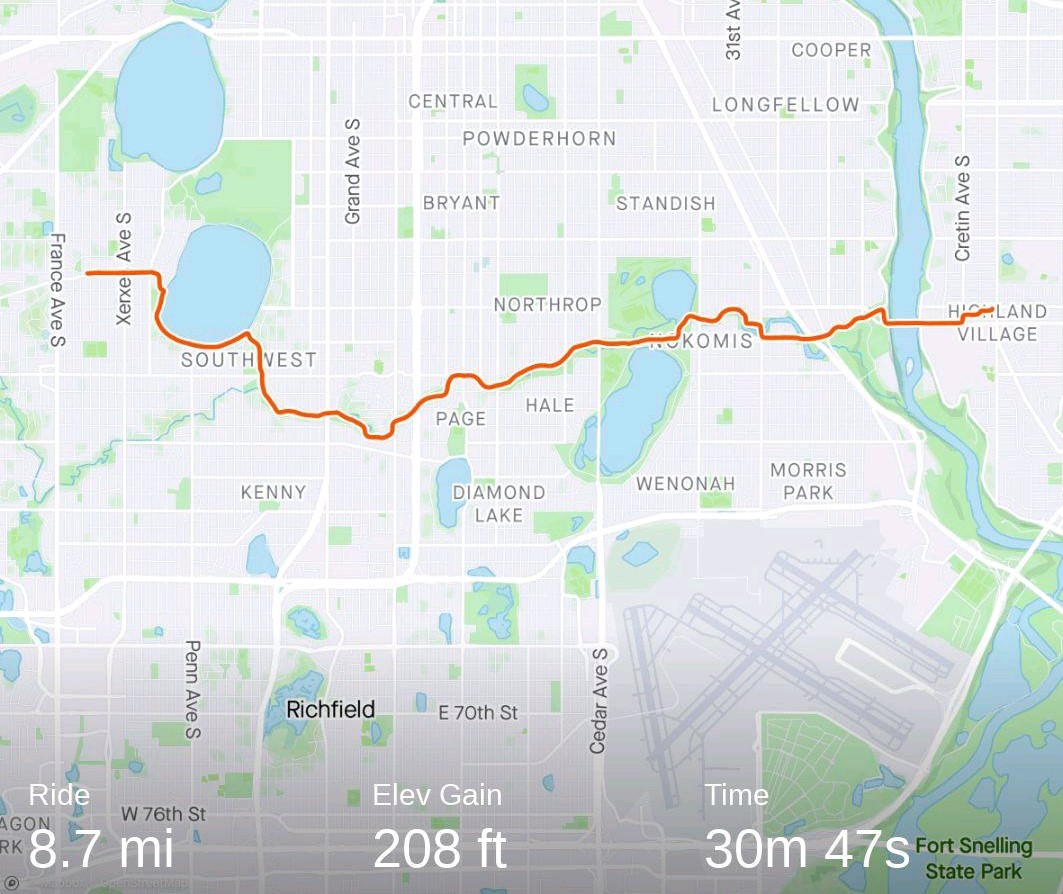

With e-assist, it's possible to maintain a near 18MPH average in an urban environment. To achieve this *average* speed, you will need to be doing 20MPH or more most of the time, and probably do some 30MPH stretches on empty city streets. This obviously can't be safely done with any kind of congestion along the route. This ride, mostly on bike trails, shows a nine mile cross-city trip taking about half an hour. With a generous use of throttle assist, the amount of energy consumption was about 15 watt-hours per mile on this efficient recumbent bike. Consumption for a 'normal' bike, with the rider pedaling, might be closer to 20 watt-hours per mile. If the rider simply uses e-assist to 'level the playing field', it's extremely reasonable to expect energy consumption to be less than 10 watt-hours/mile. At this consumption level, a battery pack rated for 500 watt-hours (0.5KwHrs) would be useful for rides up to 50 miles in length. In my experience, this average "watt-hours/mile" is the most useful metric for these calculations. To put this into perspective in the overall transportation world, a typical full-size passenger BEV ("battery electric vehicle") will consume 400 watt hours/mile or more (20 e-bikes). As always, YMMV.

Return to Top of Page Return to Main Menu