This 'high-end' wheelchair, utilizing a titanium main 'box' frame and mostly aluminum parts, weighs 30.68 pounds.

In order to determine what parts need to be replaced versus capable of being re-used and/or adjusted,

it's important to be able to inspect everything at the 'bare metal' level.

In spite of this being a 'high end' wheelchair, there is a significant amount of rust and seizing of the steel

parts, as well as corrosion of the aluminum casting parts used.

There are two main drive wheels, one on each side of the wheelchair. They are powered by the chair's user who uses their hands placed on the 'handrims,' allowing a smoother surface than gripping the tires. The handrims on this model are hollow aluminum tubes bolted to the main wheels' rims. The original rubber outside grip-strip was deemed to be a 'negative feature' and removed by the user.

Wheelchairs tend to use 24" tires, also used in the bicycle industry (although not as common as the 26" size).

Each of the two drive wheels has two bearing each,an inner one and an outer one.

This shows the outer wheel bearing on one of the drive wheels.

It is a R8-2RS ball bearing, with rubber side ("RS") seals.

These bearings were still in good condition, likely due to the fact that they are protected from the elements

inside the wheel's hub, hidden by the axle's quick-release button.

Specs for a R8-2RS bearing (per grok-3):

The R8-2RS bearing is a miniature deep groove ball bearing with the following specifications:

You can buy these R8-2RS bearings for $9/each from wheelchair dealers, OR get 10 of them for $8 from amazon (e.g., https://www.amazon.com/Sackorange-R8-2RS-Premium-Sealed-Bearing/dp/B07DCQLCS3). They are bog-standard bearings and mostly come from the same factories, often in China and Korea. There is nothing about these "wheelchair" bearings that justifies the greater than 1,000 percent markup. Still think that DOGE is without merit? A total of 8 of these bearings are needed per wheelchair. For bicycle wheel hubs, the 6802-RS and 6902-RS bearings are very common, and sometimes the only difference is whether it is an Imperial (American/SAE) or metric size. The R8 is an Imperial size.

This shows the inner wheel bearing on one of the drive wheels. It is also an R8 bearing, the same size

as the outer bearing, but with a steel side protective cover.

These bearings were seized up, likely due to the fact that they are facing the seat and subject to dirt exposure.

It will be interesting to see if the manufacturer fixed this in later models.

The wheels still turned, but there was increased friction because the inner bearing surface rubbed against

the axle shaft.

Bearings on wheel chairs don't "wear out" since these bearings are made to last for thousands of miles

in transport terms, while most wheelchairs probably only travel hundreds of miles during their lifetime.

They "fail" because they get contaminated by the elements in the envirnonment in which they are used.

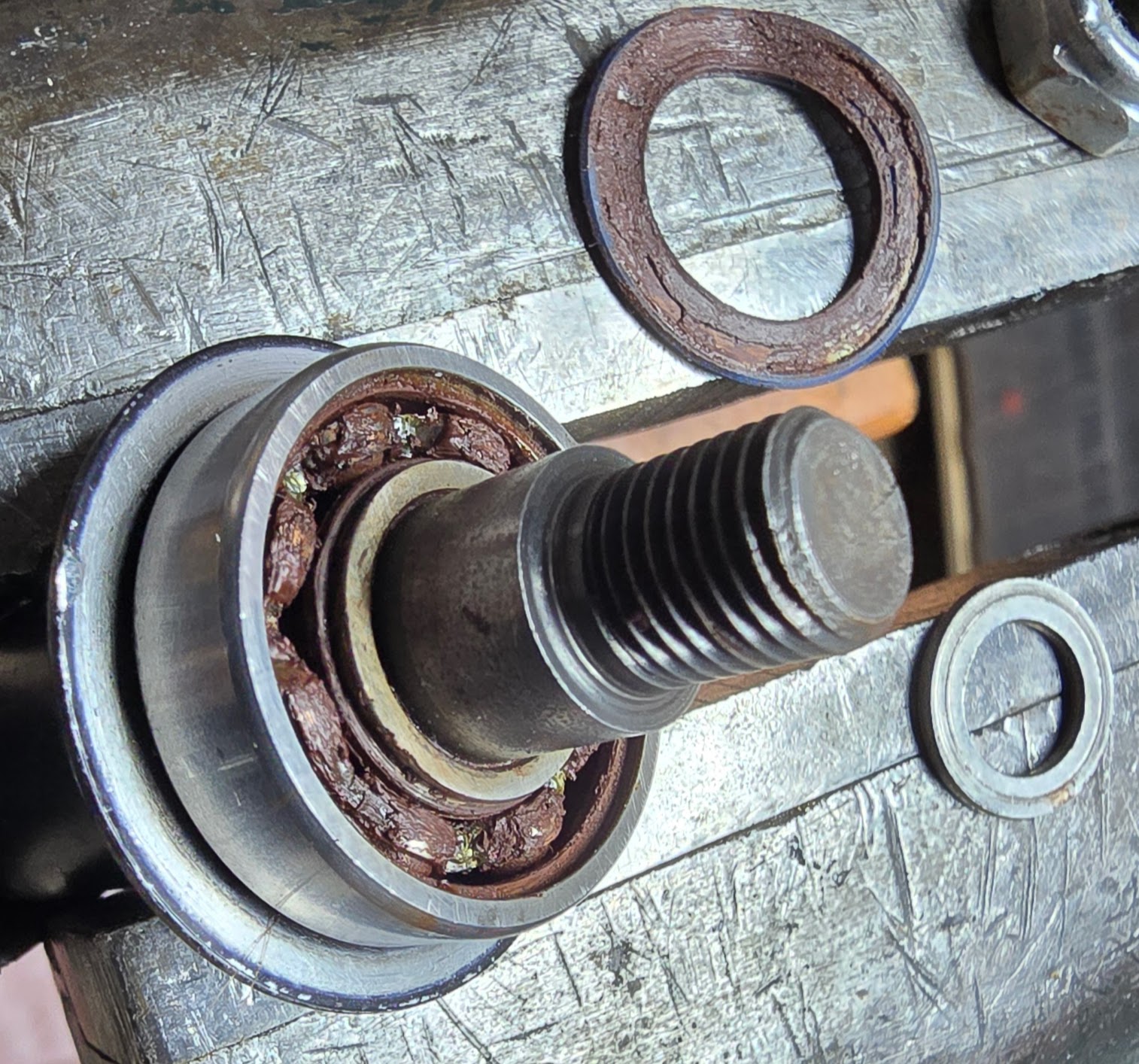

This bearing, the top one in one of the swivel wheel fork supports, accumulated enough water over a number

of years to wash out the lubricant and cause surface rust inside the bearing. Removing the protective seal,

which in this case didn't do its job very well, shows the resulting mess. If caught early enough, the bearing

can be cleaned out and relubricated manually, adding years of future use to its life.

There are two of these for this wheelchair, one on each main wheel. They are not really 'brakes' in the sense

that they are used to slow the wheelchair, but to lock the wheels so that the wheelchair doesn't move.

They are functionally used as 'parking brakes.'

This photo shows the left wheel brake prior to removal.

This is the side of the brake assembly that faces the inside of the wheelchair.

This is the view of the parking brake from the outside.

These brakes have no 'broken' parts, but the attaching hardware is rusted, and the 'pivot rivet' articulating joint pins need to have their nylon bushings replaced. These rivets would have to be drilled out to be removed, requiring replacement rivets (hinge pins) as well. The main issue here is that these parts are not likely to be separately available.

We ended up replacing the brakes/wheel locks with a set from amazon ($46) for a 1" tube (as measured with a digital caliper).

Each of the two caster (forward) wheels has two bearings each. Each of the caster wheel swivel forks

also uses two bearings. If any of these eight caster bearings have excess play it will result in a wobble in

the caster wheel at higher speeds.

This shows one of the two bearings used in each caster fork (front wheel swivel) assembly.

Per the model number, they are the same bearings used for the main drive wheels.

By: TiLite - Permobil

Part Number: HD100011

Description: BEARING 1/2"ID X 1-1/8"OD X 5/16"

You can buy these R8-2RS bearings for $9/each from wheelchair dealers, OR get 10 of them for $8 from amazon (e.g., https://www.amazon.com/Sackorange-R8-2RS-Premium-Sealed-Bearing/dp/B07DCQLCS3). They are bog-standard bearings and mostly come from the same factories, often in China and Korea. There is nothing about these "wheelchair" bearings that justifies the greater than 1,000 percent markup. Still think that DOGE is without merit? A total of 8 of these bearings are needed per wheelchair.

There are two of these for this wheelchair, and both are mounted forward of the main wheels and keep the chair

from tipping forward. The wheels are mounted in forks which allow continuous swiveling around a 360 degree

circle. These nominal "8 inch" pneumatic wheels are designed to be inflated via a Schrader automotive type valve.

The bearings used on the caster wheels are significantly smaller than the other bearings used on this chair. The identifying markings on these are no longer legible, but the axle size is 5/16" (???) and the bearing's outer dimension is 1" (???).

Q for grok-3 (XAi.com): For the wheelchairs made by TiLite in 2008, was the hardware (nuts and bolts) used metric or American (SAE)?

Grok's reply: In 2008, TiLite wheelchairs primarily used SAE (imperial) hardware for their nuts, bolts, and other components. TiLite transitioned to metric hardware in 2018, as noted in multiple sources, meaning all their wheelchairs produced before this change, including those from 2008, were built with imperial-sized hardware. For example, a Reddit discussion about a pre-Permobil TiLite ZRA mentions screws in inches (e.g., 1/4"x28 fine thread), reinforcing that older models used SAE standards.

If you need specific part details or replacements for a 2008 TiLite model, you may need to consult the owner's manual or contact a supplier like DME Hub, as imperial parts for pre-2017 models are no longer supported by TiLite and may be considered "out-of-stock."

The use of unprotected steel nuts and bolts makes standard removal techniques impractical for some assemblies.

Here a nut needs to be removed with a disc grinder to allow removal of the seat mounting adjustment arm.

The arm is made of plastic, so heating with a torch is not an option.

The photo below shows a crack in the titanium main 'box frame' tubing. This was hidden by the wheel assembly mounting bracket, which also had the effect of keeping the crack from breaking further. The clamping force of the mounting bracket may or may not prevent the frame from failing in the future.

TiLite's advertising claims for this model include this:

"The Tru-Fit System opens up the world of adjustability by incorporating an infinite adjustment mechanism. The Tru-Fit system allows you to fine-tune the fit of your chair because you are not limited to a series of pre-set holes. Also, instead of bolting through frame-weakening holes, components clamp directly onto the frame. This eliminates one of the main stress points on today's wheelchairs by reducing the number of holes in the frame."

Unfortunately the photo of this crack shows that TiLite's strategy didn't go far enough.

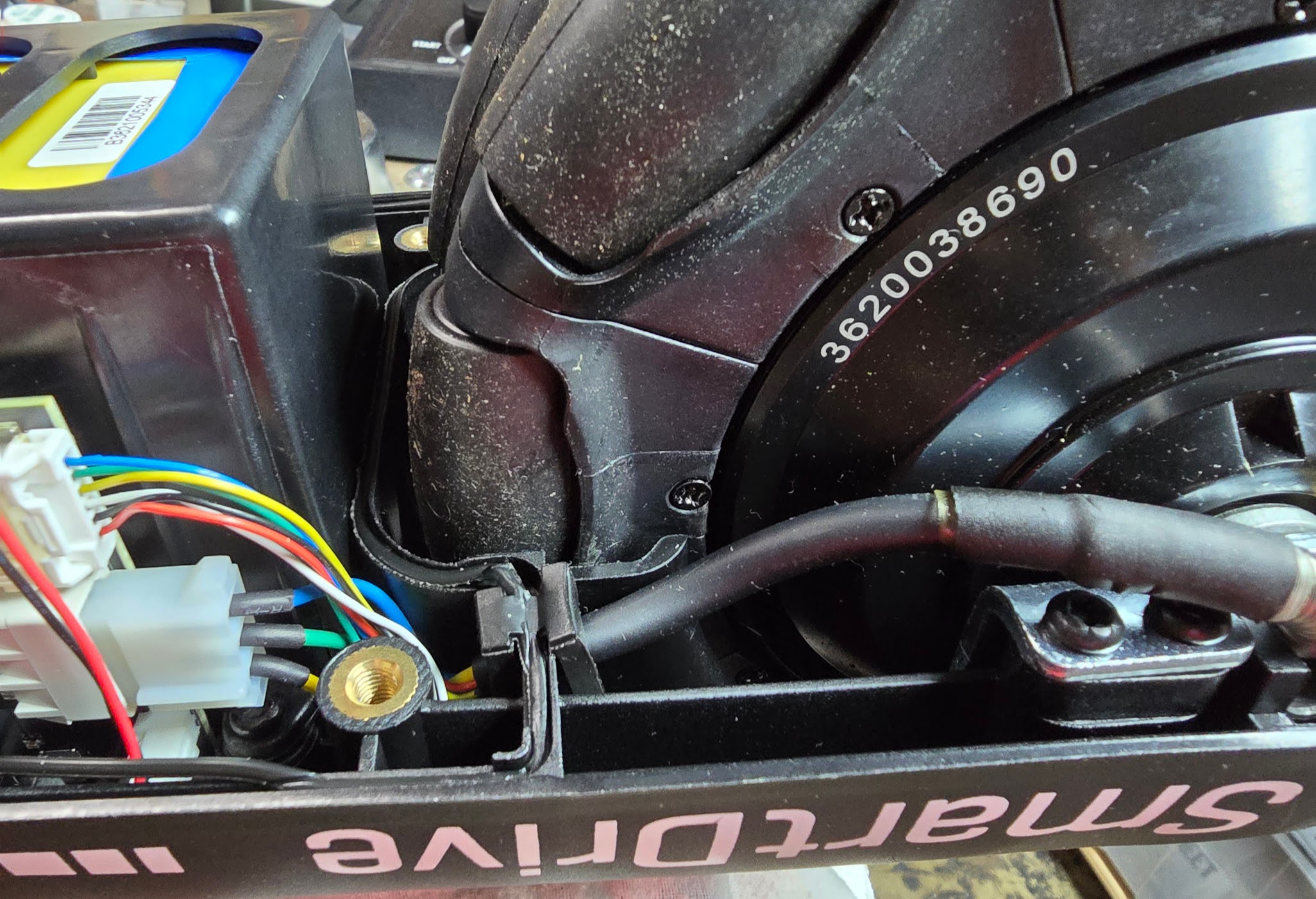

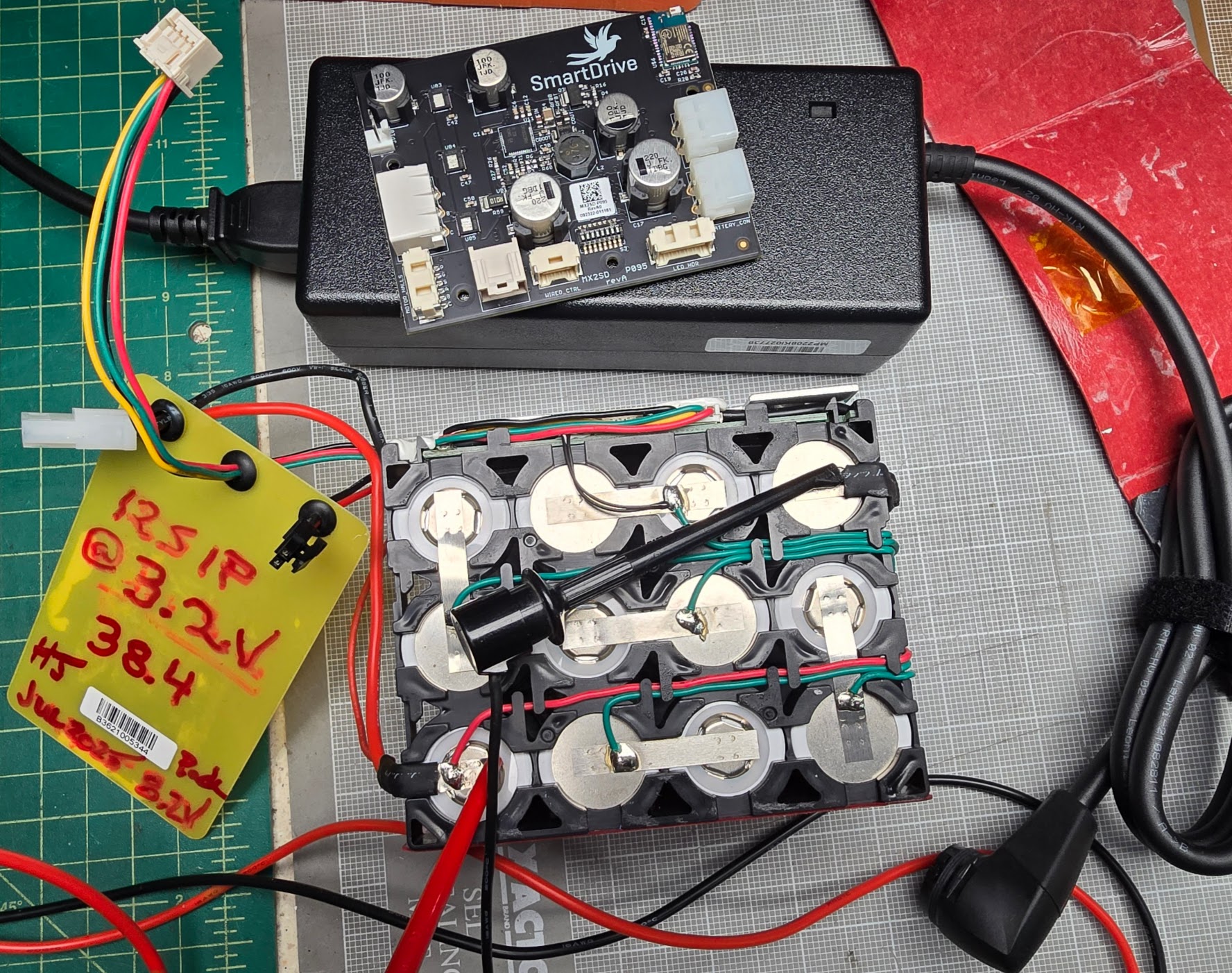

Showing left side of the SmartDrive unit with the top cover off (6 Torx T15 screws). The cover may have been previously removed, unless the factory didn't do a good job of seating the thin sealing gasket which seals the case.

It appears to be a direct drive BLDC motor with the 3 larger phase wires (blue, green, yellow) on one connector, and the smaller Hall sensor wires (blue,green,yellow) 5V power wires (red,black), and a white wire -- probably for motor heat sensing -- on the other connector. j

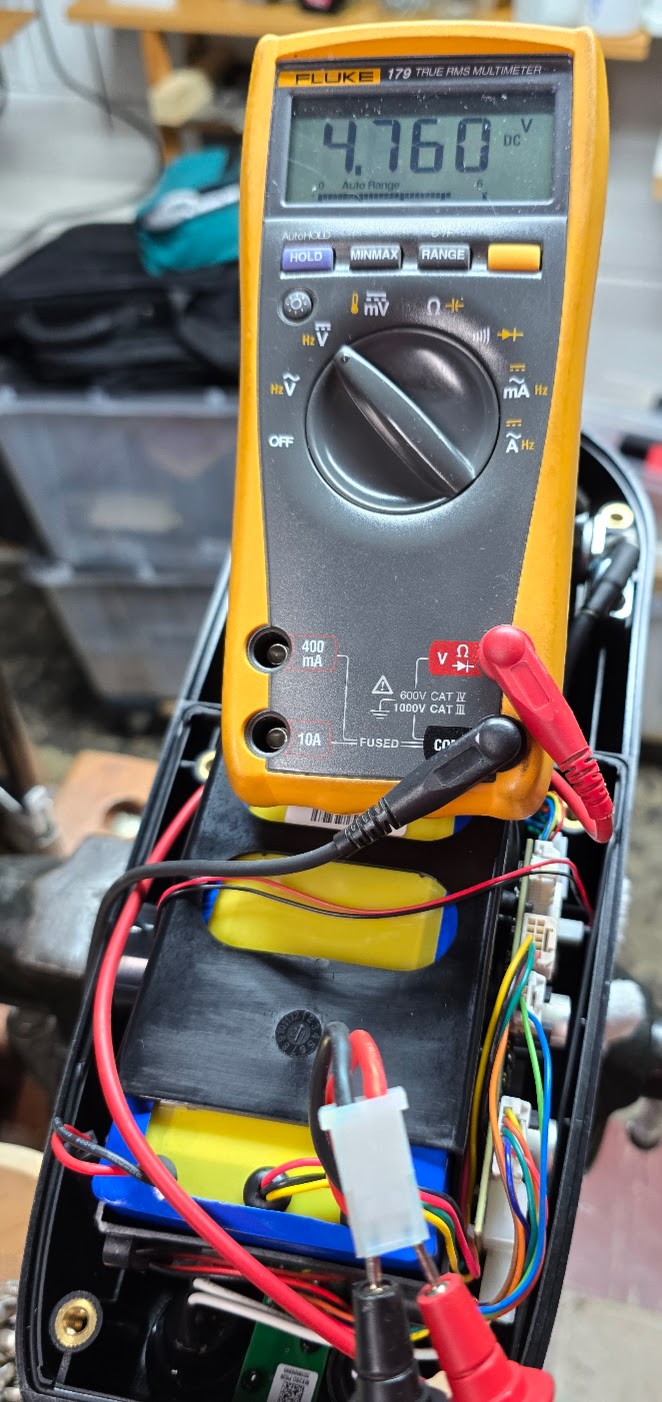

This shows the battery pack (in blue shrinkwrap) and the SmartDrive controller board (black, with a bird logo) removed from the black plastic housing which is mounted inside the SmartDrive unit. The controller contains the electronics that allow the user to make the drive operate, including the radio circuitry allowing remote control.

Note on the Warning label, #5, the instruction regarding storage of the battery requiring periodic recharging. This is to keep each cells voltage from dropping too low, which can destroy cells using lithium chemistries. This is especially true if a cell remains at a too-low voltage for too long a time.

Although the meter is showing less than 5 volts on the red and black power leads going to the battery, this can't yet be relied on to tell us each cell's voltage level. We need to know whether these leads go directly to the cells or whether there is still a BMS in between. We'll have to remove the entire battery assembly to peel back the insulating layer on top to find out. If it's a BMS, we still don't know what the individual cell voltages are. We think it's a 10S pack (36V motor operating voltage), but will verify that once we see the cell arrangement. Also, our guess about it being a 10S is based on assuming the cells are li-ion chemistry (@3.6V).

There are no visible balance wires going to the SmartDrive controller board, so the most likely place for a BMS would be on top of the cells themselves.

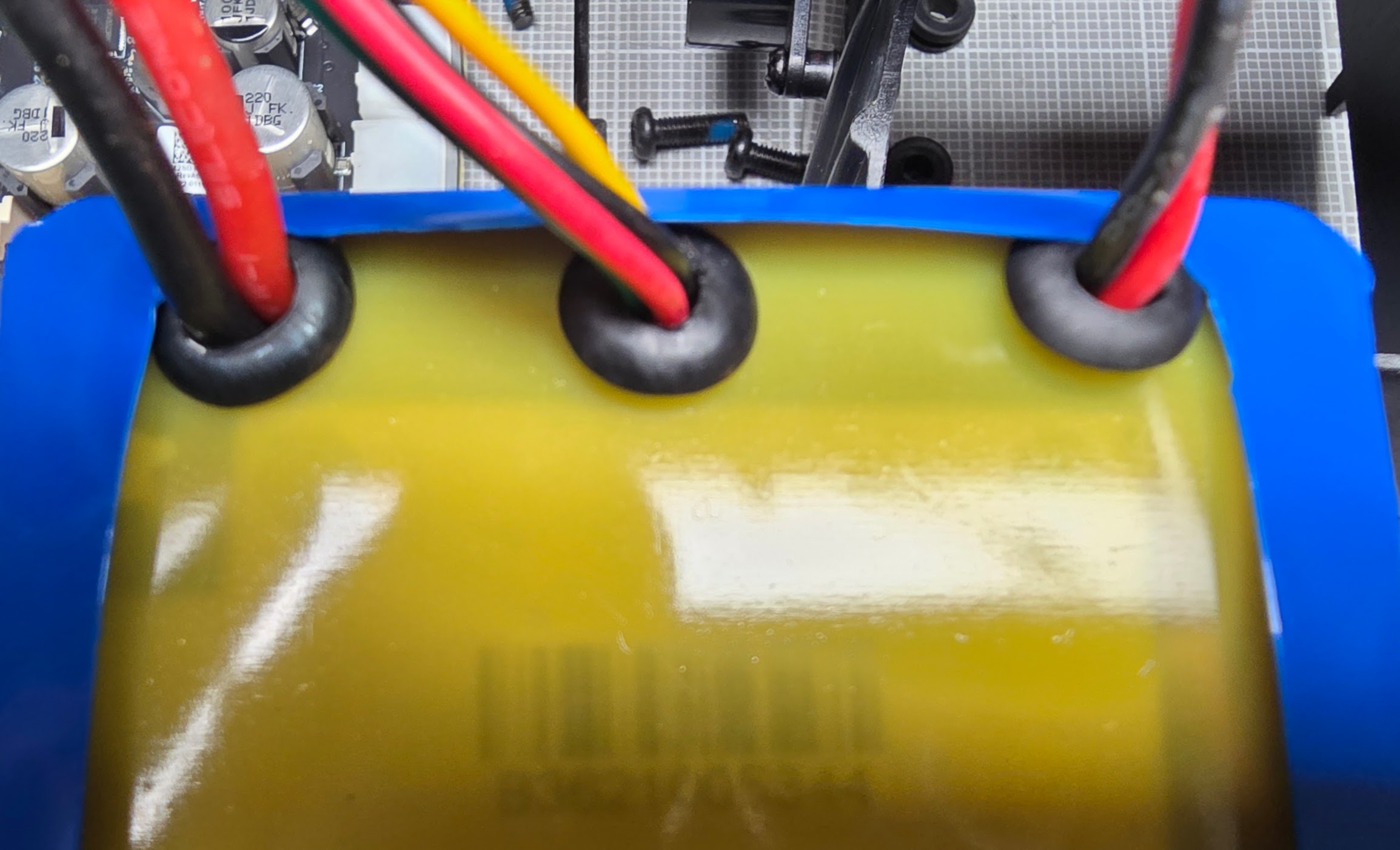

Showing the wires coming out of the battery pack. The presence of a separate barcode (starting with "BS3621...") under the yellow top insulating/protective cover lends credence to the existence of a BMS under this cover.

It turns out that there was a BMS under the yellow insulating layer. Note the edge connector on the right side of the photo with one thin red wire and 12 more green wires. It is very common for a BMS to use these thin wires to 'balance' the cells, meaning that each cell in the string is operating at the same voltage as all the others. If these are in fact the 'balancing' wires, it means that this is a 12S pack, not a 10S pack. There is typically one more wire in the balance connector than the number of cells connected in series (see photo below).

Here we see the side of the pack that was directly under the BMS (now removed). It shows the balance wire connector, the 12 green and 1 red wire, and the barcode and other cell-identifying information. Note the "LFP" which identifies this cell as using the "lithium iron phosphate" chemistry. Remember from your high school chemistry class that "F" (ferrous) is the symbol used to denote "iron" on the standard atomic chart.

The 26650 refers to the size of the cell, which in this case is 26mm wide by 65mm tall. Each cell's nominal voltage is 3.2 volts. Each cell's capacity is 3.3 amp hours, or in terms of stored energy, 10.56 watt hours (3.2 x 3.3). Since there are 12 cells, the pack's total energy storage capacity is 126.72 watt hours (10.56 x 12).

The red/positive wire in typical fashion goes straight through to the positive end of the 12S1P (@ 3.2V) pack, but the black/negative wire goes to the BMS, where all the functions of the BMS prevent getting a true reading of pack voltage. It turns out that SmartDrive chose to use the li-po (lithium iron phospate) cell chemistry, which at 3.2v operates at a slightly lower voltage than the li-ion of 3.6v. The resulting nominal pack voltage is thus 38.4 volts (12 x 3.2). The advertised (per the manual) voltage of this pack is 36 volts. The *actual* voltage of this abnormally discharged packed when opened up was ~ 8 volts. which equates to less than 1 volt per cell -- a potentially destructive level.

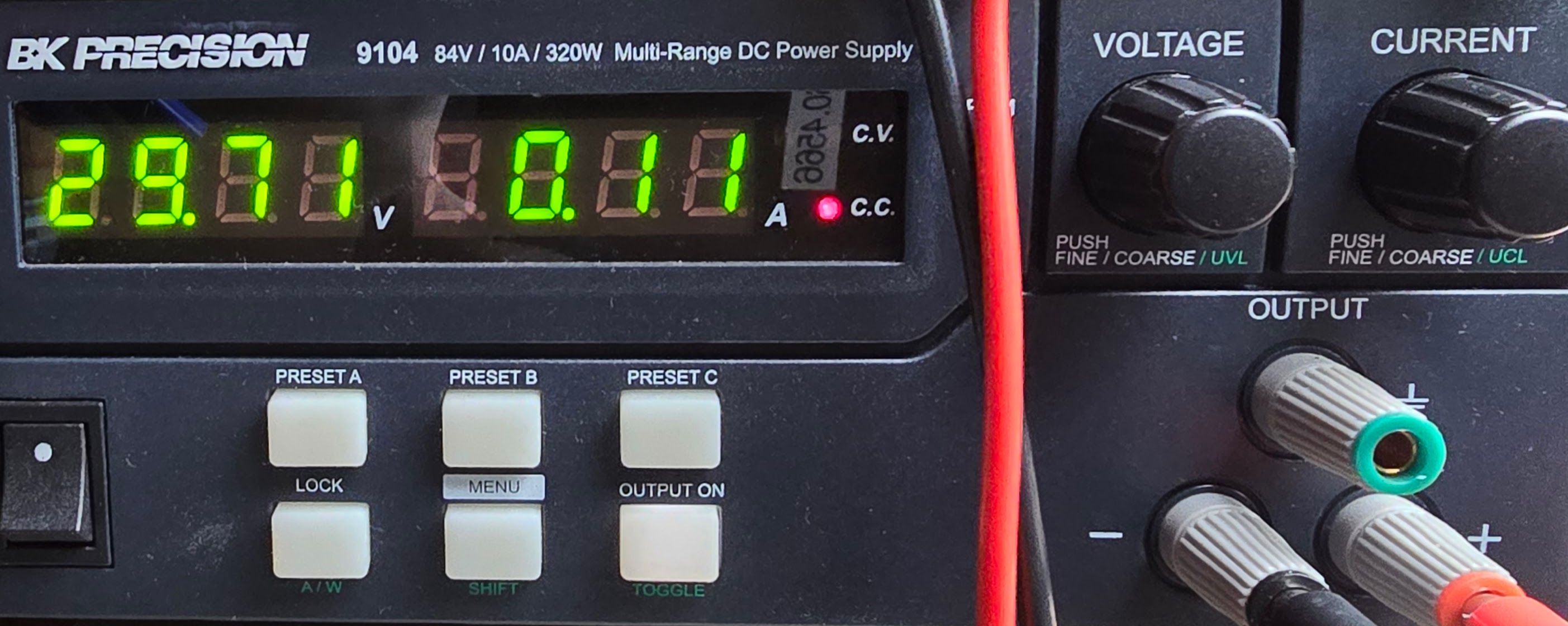

Next we use a constant current/constant voltage bench power supply to see if this pack can be brought back to its normal fully charged voltage of approximately 43 volts (3.6v x 12 = 43.2v). The charger that came with this SmartDrive unit will not charge this battery because it thinks the pack is dead.

We started by trickle charging (~ 110 milliamps of current maximum) in 5 volt intervals. The idea is to see whether the pack will accept a full charge, without stressing it in the process. Here we are heading from 25 to 30 volts of charge at the maximum allowed 110 milliamps.

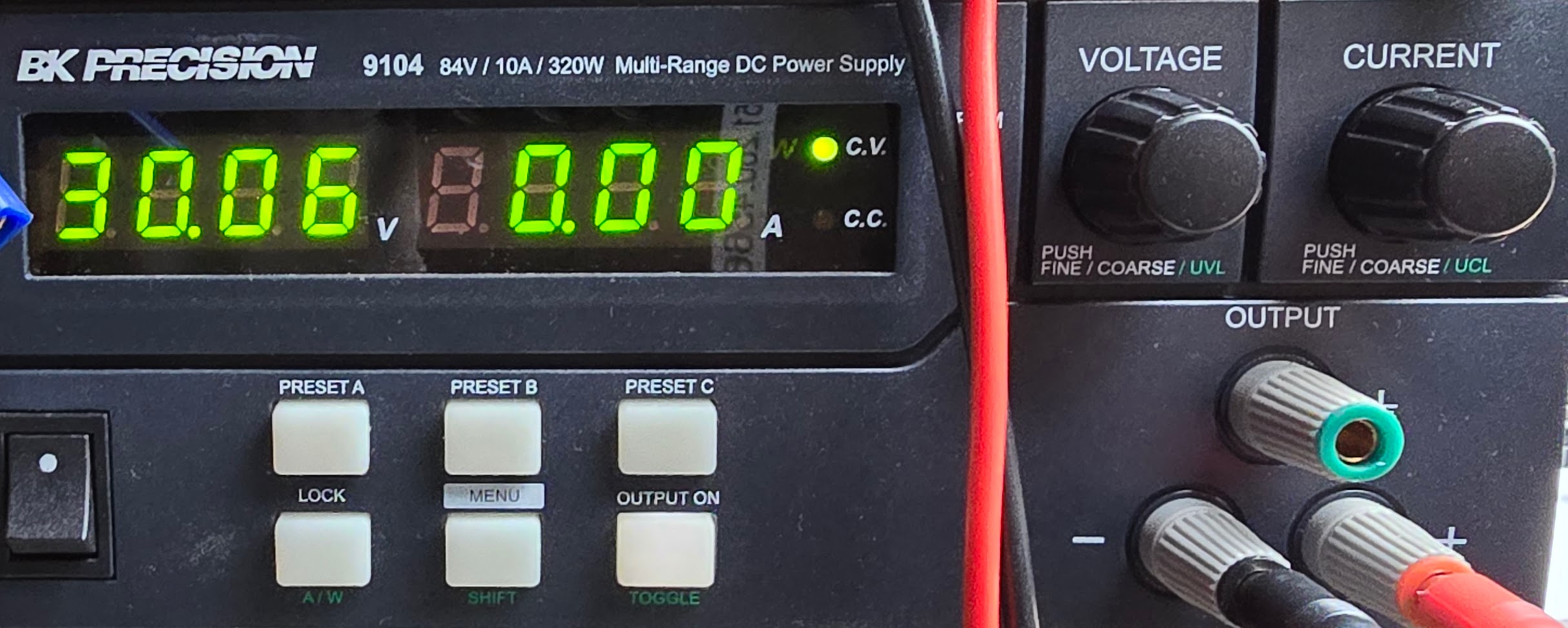

After about several hours the current going into the battery has tapered off to nothing, and the power supply is simply applying a constant voltage of 30 to the pack, allowing all of the 12 cells to stabilize. If the pack manages to reach a voltage of 40 and slightly above, we'll let it rest on the bench for a period of days to see if it can maintain its charge. If it exhibits any significant self-discharge without a load being attached to it, it's a sign that the cells have sustained too much chemical damage to be of future use. If the pack doesn't self-discharge, the next part of the testing process is to see if it is able to deliver the full amount of energy stored in it, and to repeat that cycle several times. If it passes all these tests, the battery can be deemed to 'have survived' the state of discharge it was subjected to.

The remaining issue is that even if the pack passes all of the above tests, should it be used. The prevailing wisdom is that it should not be used in a normal environment, even though the 'lithium iron' chemistry used in this pack is considered to be safer than the 'lithium ion' chemistry used in other packs.

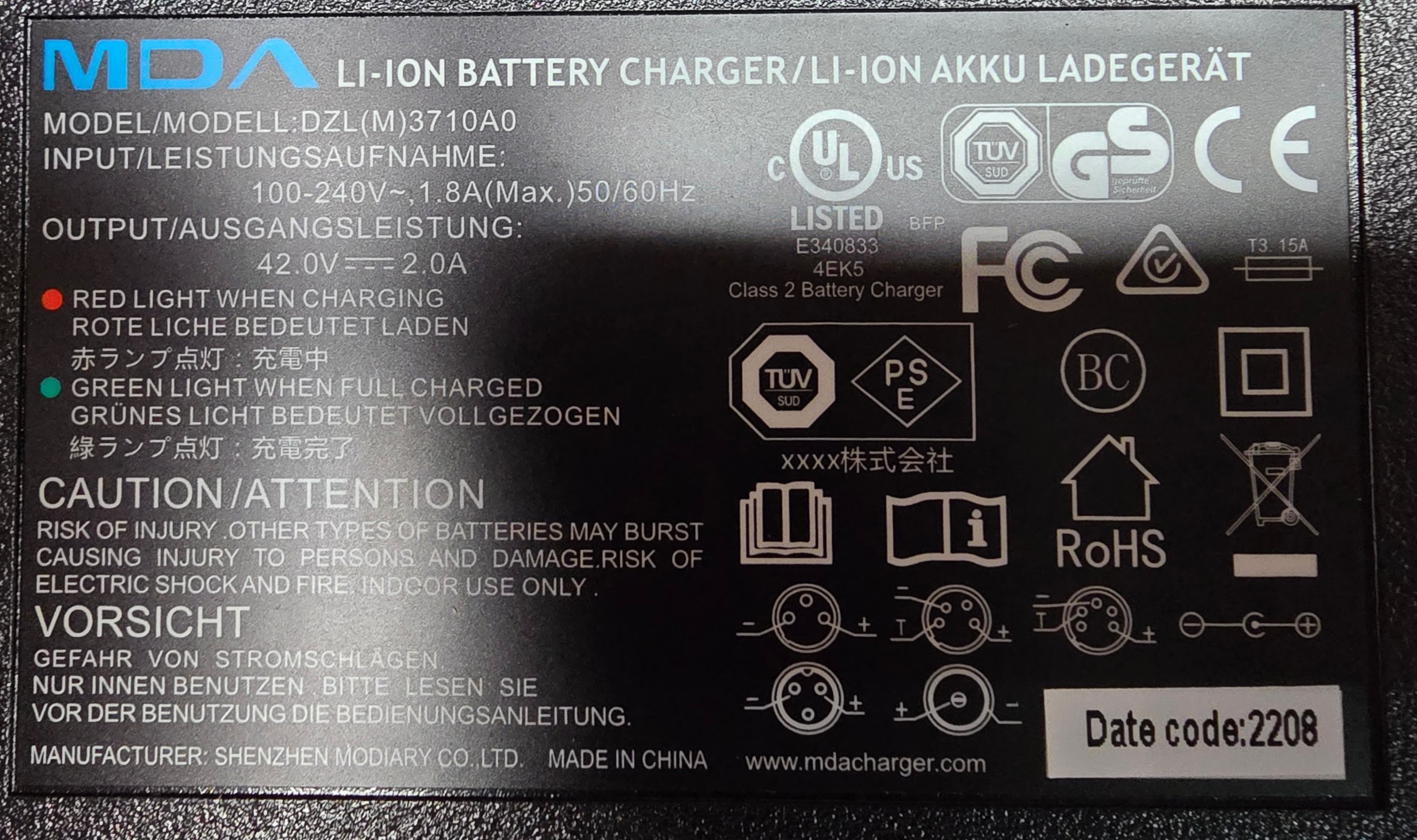

This shows the label on the factory supplied charging unit. It's rated DC output (charging) voltage is 42V at two amps. This means that this charger is supplying up to 84 watts of power during the charging cycle. If the battery pack passes all of our manual tests, we will attempt to do several charge cycles using this factory charger.

Allowing 'remote control' of the SmartDrive unit, a SiLabs bluetooth low energy module is mounted on the main control board. SmartDrive supplies a custom designed wristwatchv (TicWatch E3) which allows compete control of the drive unit via bluetooth radio technology.

https://www.southwestmedical.com/replacement-parts/tilite/tilite-2gx/crosstubes/15-wide/1-crosstubes (see ), Display a PDF file ... (PDF, # pps, 20??)

Return to Top of Page Return to Main Menu